Linear filler with 8 nozzles LF8-4000

Linear filler with 8 nozzles LF8-4000

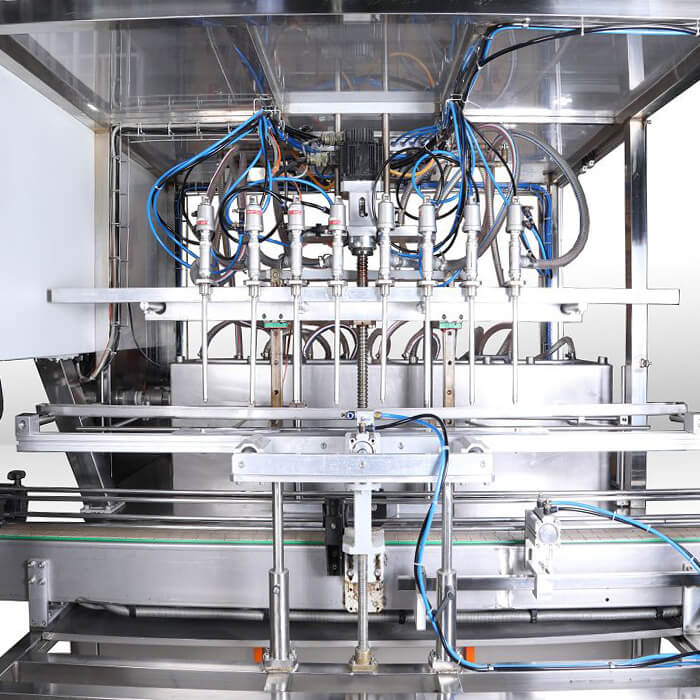

LINEAR FILLER WITH 8 NOZZLES LF8-4000

Linear filler with 8 nozzles LF8-4000

The use of liquid filling machines in the pharmaceutical, food and detergent industries with high injection speed and accuracy is the most important element in increasing the productivity of the production and packaging lines of this industry.

Description

The use of liquid filling machines in the pharmaceutical, food and detergent industries with high injection speed and accuracy is the most important element in increasing the productivity of the production and packaging lines of this industry. The main design of these devices are divided into three pump, gravity and piston types based on the injection system, and the JSM series, by making its piston type for a wide range of thin and thick liquids with high speed and accuracy, answers many problems of the pharmaceutical, food and detergent industries. .

Features of the LF8-4000 device:

- All steel body, conveyor, tank and nozzles

- Suitable for various bottle sizes

- Ability to change the number of nozzles

- Accurate injection volume due to the use of a separate piston for each bottle and the Angle Valve of the nozzle head

- It has an anti-foam movement mechanism, especially for thick liquids

- Using a drip system to prevent wastage of materials

- Fully automatic tank charging system with a capacity of 200 liters from the main mixer

- Easy and quick change of filling volume and bottle type without changing mechanical parts

- Using servo motor and ball screw for high accuracy and quick changes

- It has storage memory for various volumes and bottles

- PLC and HMI system for convenient operation

- Using Actuator and Angle Valve against acid for complete automation

- The long life of seals due to the use of sealing O-rings and anti-acid packings

- Anti-acid hoses and fittings

|

Electricity consumption |

3PH-380VAC-25A |

|

Consumable wind |

30 lit/min |

|

Nominal production capacity of 1 liter |

Up to 3200/hr |

|

Nominal production capacity of 2 liters |

Up to 2400/hr |

|

Nominal production capacity of 4 liters |

Up to 1300/hr |

|

Bottle volume |

300 cc -4000 cc (capacity can be increased if needed) |

|

bottle height |

150 -320 mm (changes are possible if needed) |

|

Bottle diameter |

60-250 mm (changes are possible if needed) |

|

Permissible pH |

PH<8.5 (contact JSM consultants to use higher pH) |

|

Fluid viscosity |

0.9-5000 cp |

|

tank volume |

200 liter |

|

Type of tank |

Steel 316 |

|

Type of nozzles |

Steel 316 |

|

Connections and fittings |

PTFE AND Steel 316 |

|

Floods and dams |

FKM , PTFE |

No Comments ...