Get in touch with us

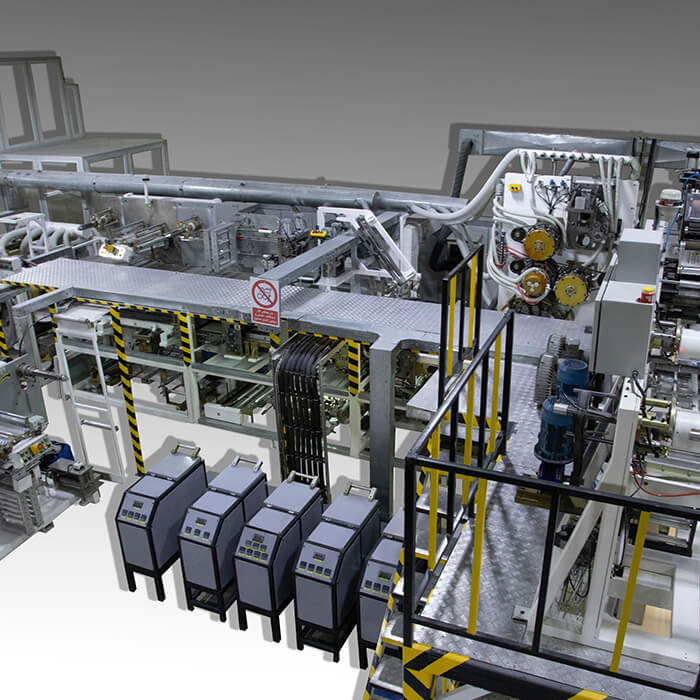

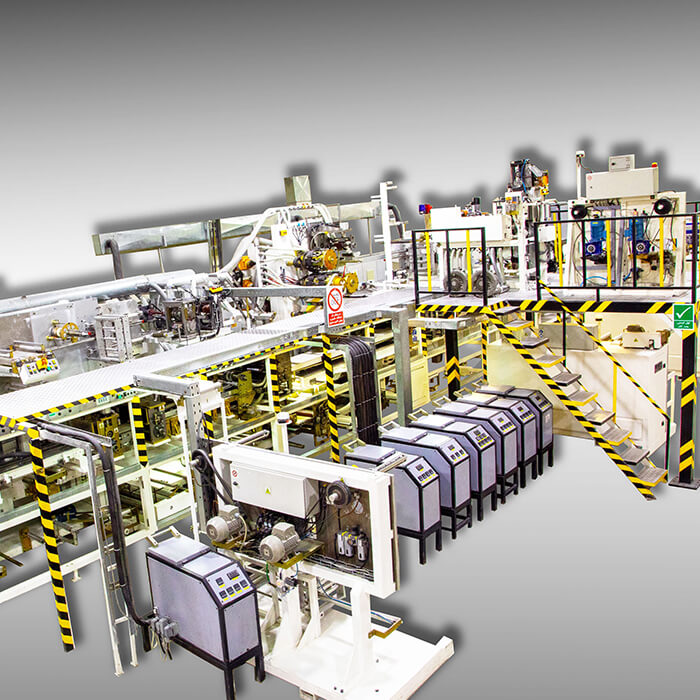

Glue tank system

Description

The hot glue tank unit is used to melt thermoplastic adhesives and transfer them to the place of use (applicator, module and nozzle). All the parts of this system with the original model of NORDSON company including aluminum tank, gear pump with accurate flow rate adjustment (Metering Pump) with pump applicator and material transfer thermal hoses, without any restrictions on dimensions, tank capacity, number of pumps and flow rate, in the set Machinery is designed, built and operated for different applications.

Features of glue tank unit:

- The capacity of the tank is 9 kg to 50 kg (it can be changed according to the order)

- Die-cast aluminum body with Teflon coating for complete tank drainage

- Interchangeable rod elements

- Intelligent temperature control

- It has a precise gear pump (METERING PUMP)

- The ability to make steel pumps for corrosive materials

- It has an all-steel filter with a compact design

- It has a safety valve and a BY PASS route for the pump

- Use of thermal seals with long life

- Ability to install level switch and alarm to control the glue level inside the tank

- Has thermal insulation to increase efficiency

- The mass flow rate of the whole unit is 5kg/hr to 15kg/hr (numbers vary according to temperature, glue type and engine speed.)

- Replacing and servicing the pump without the need to empty the tank

- HMI and PLC display for precise and easy adjustment

- It has an inverter and a network for synchronizing with the line

No Comments ...