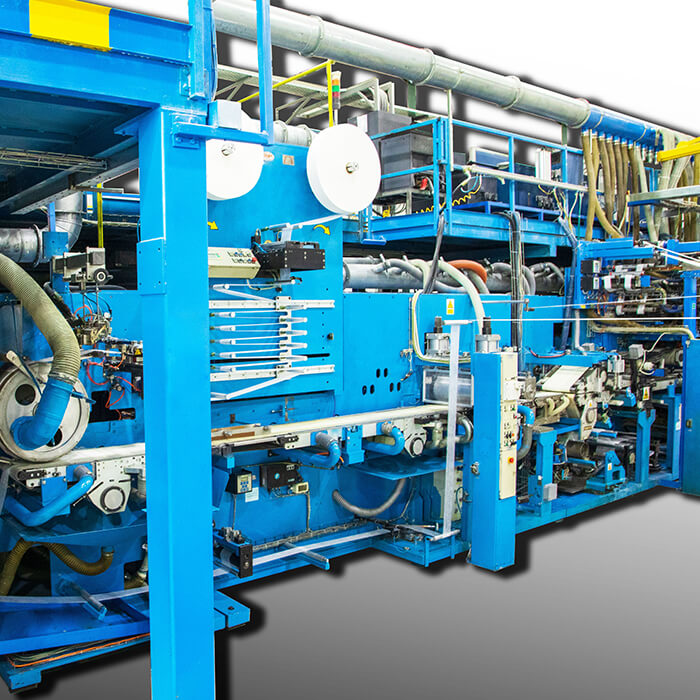

Diaper production line

Description

JSM Machinery Group is the first designer and manufacturer of complete diaper production line in the Middle East. This group has the ability to produce the most up-to-date parts, options and machines of the cellulose industry, especially diapers, by using its electrical, mechanical and control expert teams. All parts and options are designed and manufactured inside the collection and after assembly, they are set up by experienced experts. JSM Machinery has been able to bring exemplary security to manufacturers with its after-sales service and production line setup as well as unparalleled support.

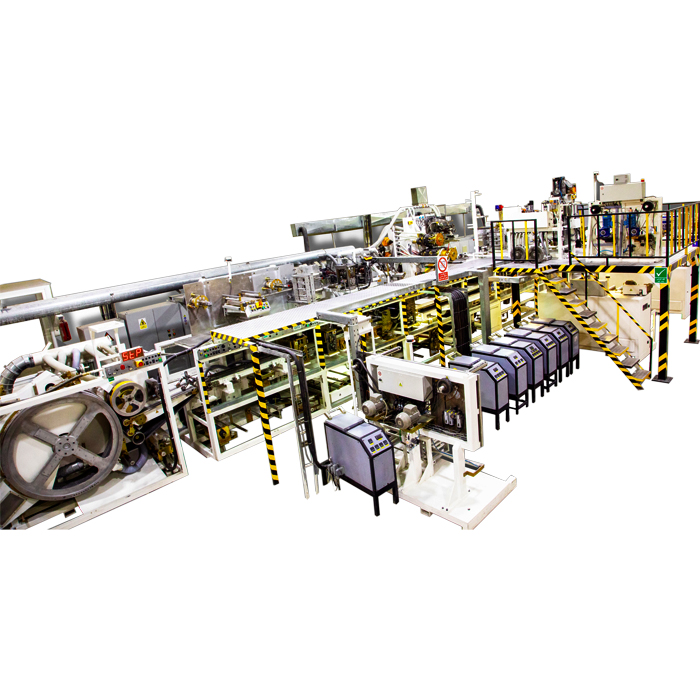

Baby diaper production machine

Attributes :

Production capacity of 350 fillings per minute (can be upgraded to 650 according to the order)

Ability to produce various sizes of diapers from size 0 to size 6

Synchronization of more than 18 units with servo motor in the device and their intelligent programming in order to produce high quality product and very easy operator.

with automatic position setting (Auto Position)

Automatic roll changing system with splicer and smart dancers

The ability to operate the device at different speeds by selecting start, JOG and speed reduction key modes

Manual start capability for each engine for testing and adjustment.

Semi-automatic product packaging system (Stacker) with the ability to set the number (8, 12, 20, etc.) of filling in each package. If needed, the fully automatic packaging system can also be installed on the device.

It has a roll tear detection sensor with an alarm

Smart roll tension adjustment

Intelligent temperature control system

It has a local powdering option in addition to the regular powdering system

Easy and fast resizing

It has the ability to install a smart image processing camera for product QC (waste control camera).

The ability to install a Remote Control system to adjust and fix problems with the modem

Elastic Ear option

Option cache 3D

2FOLD absorbent mass option

Hypoallergenic option (acquisition)

Thermal sewing option (rotary oven)

Ultrasonic sewing option

3D drama

It has a production and waste reporting system

It has a recycling system to reduce the waste of pulp and SAP powder

The use of superalloys in the construction of strategic parts with long life

Using the Hot Melt glue system with tangential and spray nozzles made in JSM with the model of NORDSON company

Hammer-Mill made of super alloy with long life and excellent quality of milled paste

It has an air cleaning system

|

main electricity |

3PH-380VAC-50Hz |

|

production capacity |

350/min (can be upgraded to 650/min) |

|

Main body material |

Carbon Steel |

|

nozzle type |

Direct contact (tangential) and types of sprays (Algro, Signature, Spiral, etc.) |

|

Hot Melting System |

8 devices with NORDSON design (changes depending on the type of device options) |

No Comments ...